Shirin Duba ingancin Bututu Karfe

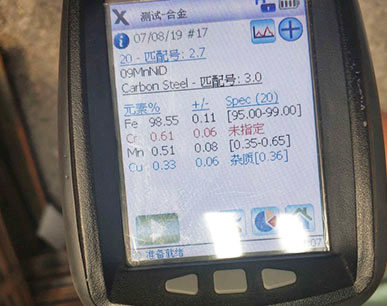

Gano girma, Binciken abun ciki na sinadarai, Gwajin mara lalacewa, Gwajin aikin jiki da sinadarai, Binciken Metallographic, Gwajin tsari.

Auna diamita na waje

Tsawon tsayi

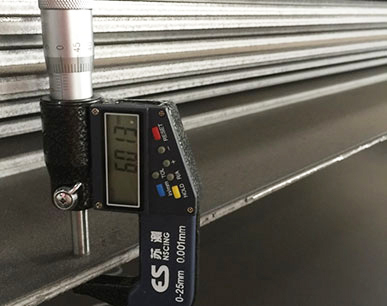

Auna kauri